How Boiler Feedwater Quality Can Affect Boiler Operations

A large majority of boiler water problems have their root cause from impurities and contamination in the feedwater system. This should be a clear indication of how critical feedwater quality is to the health of a boiler water system.

For anyone treating the water within a boiler system, it is important to understand the unique qualities of water and steam generation, as well as how the makeup of the feedwater you use can affect your boiler water system.

Boiler feedwater quality

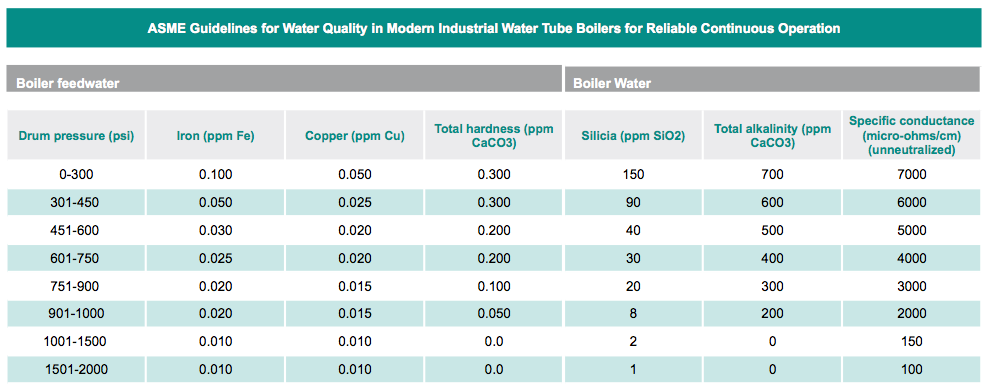

Impurities in feedwater can cause boiler water system problems, and even total failure, so careful consideration to the quality of the water must be given. There are designated limits to the amount of impurities allowed within a boiler. These limits vary depending on the boiler steam pressure. Feedwater that does not already meet these requirements must be pretreated to at least partially remove its impurities.

Impurities found in boiler feedwater

All water contains various amounts of impurities. These contaminants include suspended matter, which does not dissolve in water, and dissolved matter, such as minerals. Boiler water can also contain impurities such as hardness, total alkalinity and silica. The sum total of all of the minerals and ions dissolved in a given water system makes up the Total Dissolved Solids (TDS). A boiler system will have a TDS limit, dependent upon the system’s operating pressure, which denotes the maximum number of total dissolved solids the feedwater can contain.

Risks of using low quality boiler feedwater

The impact of boiler feedwater quality on a boiler water system can be significant. Poor-quality feedwater can contain traces of various impurities, such as iron and copper, that can negatively affect the overall boiler system.

Let’s look at a commonly found impurity, iron, which can be soluble or insoluble. Insoluble iron in boiler feedwater may clog strainers and valves and cause sludge build up in some areas of a water system. It can also lead to boiler deposits and tube failure. Soluble iron, on the other hand, can interfere in some commercial processes, such as printing or cloth dying, and leave stains in domestic water systems at very low levels.

Understanding the makeup of your boiler water can help you prevent and address problems that can occur when impurities are present at the elevated temperatures and pressures of boiler systems. Boiler feedwater that is out of specification can cause corrosion (which may lead to boiler failures) and scale (which may lead to significantly reduced efficiency or boiler failures).

If low quality feedwater is used, there is the potential to cause boiler system problems that are costly to correct. Ensure that you’re using removing and controlling impurities in your feedwater with proper pretreatment equipment and chemicals.

Questions or additional information?

If you have any questions about the importance of water quality in your boiler system and the risks of improper water treatment, please contact one of our Certified Water Technologists.